Description

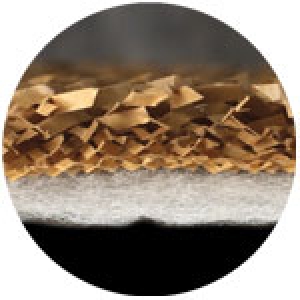

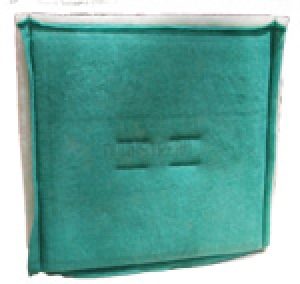

Prima is engineered to make switching from manual to automatic spraying an easy one. It’s highly user-friendly, reliable, and cost-effective to purchase and maintain. Suitable for any water- or solvent-based coating, Prima is the ideal machine for manufacturers seeking to increase productivity, reduce waste and improve finish quality and consistency. Prima is the lowest-cost machine with a working width of 1300 mm. Productivity is therefore much higher than manual spray booths and narrower automatic systems. The paper conveyor means no overspray on panel undersides and consistent panel face/edge coating. Maintenance is reduced with easy conveyor roll and filter replacement. Dual dry-filtration system combines efficiency with low costs. Request catalogue Find the dealer Contact us for more information Watch video What it does Prima by Cefla Finishing is suitable for any water- or solvent-based coating product spraying, and is the ideal machine for companies wishing to make the most of the advantages offered by spraying: increased productivity, coating product saving, and consistent panel finishing quality. — Benefits -Prima by Cefla Finishing is the first machine combining the ability to spray over a working width of 1300 mm, with the currently lowest market price for an automatic sprayer with these performances. -Its output rate ranges between 1 and 3 mt/min. Productivity is therefore much higher than in both the manual spraying booths and thelower-width spraying machines. -The disposable paper-covered conveying unit offers all the advantages of a continuous conveyor belt: no overspray on panel undersides, consistent panel face/edge coating. -The paper coil is approximately 2400 meters long and can be continuously used during various work shifts. -No machine down-time needs to be allowed for cleaning purposes at the end of the work shift : it is only necessary to regularly change the paper coils and replace the filters. -Natural air inlet that prevents coat from accumulating in the spray area. -Suction is ensured by a high efficiency fan. The inlet air goes through two-stage, large surface dry filters: the system combines high efficiency with reduced working maintenance costs.